Electric Screw Press – What is it and Where is it Used?

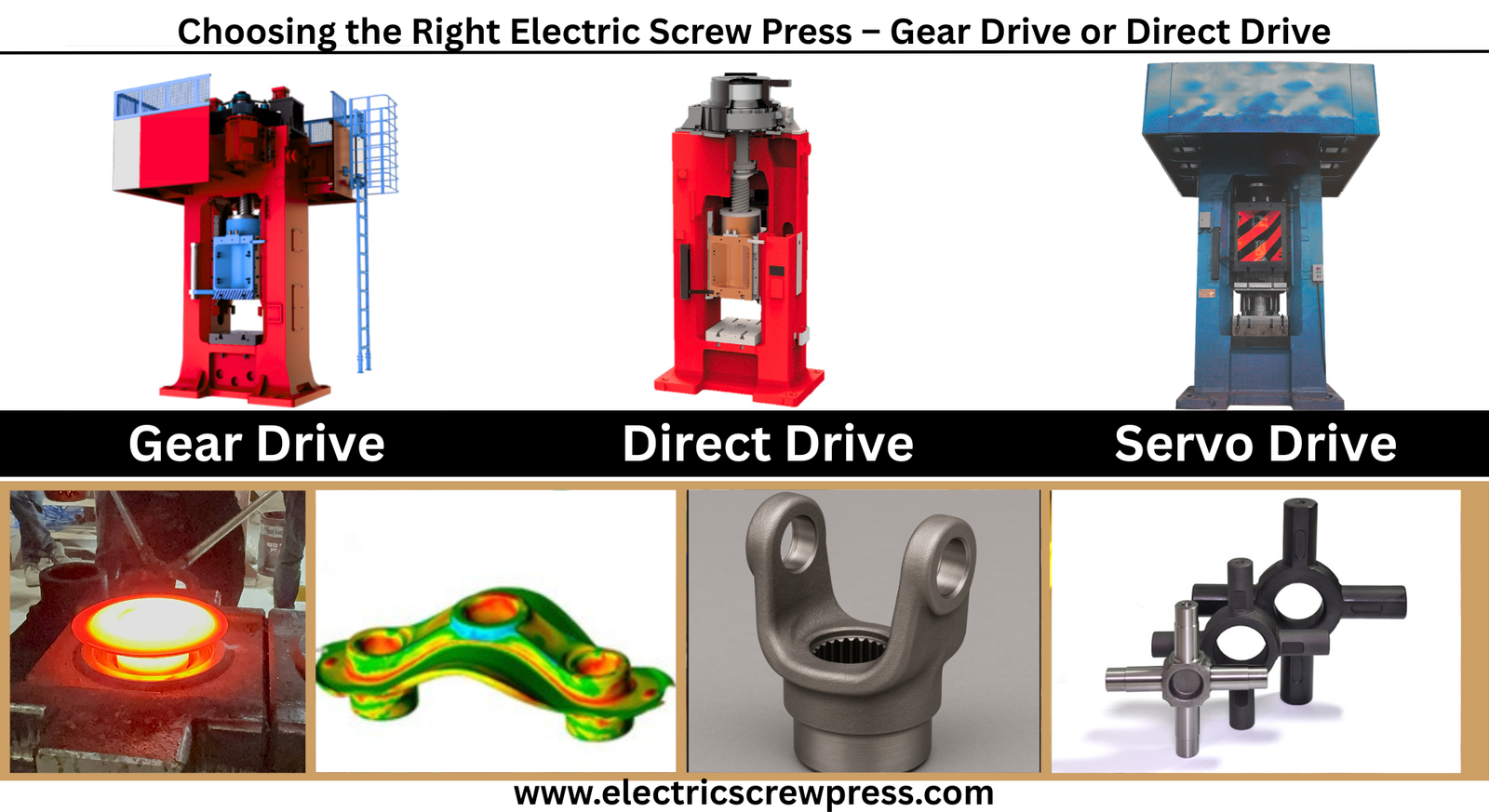

Electric Screw Press is an advanced forging machine that converts electrical energy into mechanical force using a motor-driven screw mechanism. Unlike traditional mechanical or hydraulic presses, the electric screw press utilizes a servo motor or inverter-driven system to control the ram’s movement with high precision. This allows for accurate force application, adjustable stroke, and controlled speed, making it ideal for forging operations that require intricate shapes and close tolerances. The press operates by rotating the screw, which moves the ram vertically to apply pressure to the workpiece placed between two dies. The force applied deforms the metal into the desired shape, producing high-quality forged components with minimal defects.

The primary advantage of an electric screw press is its ability to deliver high-impression forging with excellent repeatability. The electric drive system provides energy efficiency, smooth operation, and reduced mechanical wear compared to older mechanical or hydraulic systems. Moreover, it allows operators to precisely control parameters such as stroke length, ram speed, and pressing force, enabling the forging of complex and high-precision components.

Applications:

Electric Screw Presses are extensively used in closed-die forging, where metal is shaped within dies that define the final geometry. They are widely used in industries that require high-accuracy, high-strength components such as:

- Automotive: Manufacturing shafts, gears, axles, and suspension components with precise dimensions and material properties.

- Aerospace: Forging high-performance alloys like titanium and nickel-based superalloys for critical components such as landing gear, engine parts, and structural elements.

- Industrial Machinery: Production of valves, flanges, couplings, and other machine parts requiring precise tolerances and superior mechanical properties.

- Defense: Forging armor parts, weapon components, and high-strength fittings.

- Energy Sector: Components for oil & gas, power generation, and renewable energy applications.

| Model / Type | Capacity (Tons) | Stroke (mm) | Applications |

| Small Electric Screw Press | 250–400 | 200–400 | Automotive small components, industrial parts |

| Medium Electric Screw Press | 500–1000 | 250–450 | Automotive, aerospace, industrial components |

| Large Electric Screw Press | 1200–2500 | 300–500 | Shafts, flanges, high-strength industrial parts |

| Very Large Electric Screw Press | 3000–8500 | 400–600 | Heavy machinery, defense, energy sector |

| Direct Drive Screw Press | 250–8500 | 200–600 | All closed-die forging, complex components |

| Servo Electric Screw Press | 250–8500 | 200–600 | High-precision aerospace, automotive, defense parts |

Electric Screw Presses are preferred over traditional forging methods because they reduce material waste, improve die life, and ensure consistent quality. Their energy-efficient design lowers operational costs while maintaining high output rates. Additionally, with PLC-based controls and automation options, these presses can integrate seamlessly into modern forging production lines, enabling process monitoring, simulation, and predictive maintenance.

In summary, the Electric Screw Press is a highly versatile, energy-efficient, and precision-driven forging machine, ideal for producing complex, high-quality forged components across automotive, aerospace, industrial, defense, and energy sectors. It represents the modern evolution of forging technology, combining mechanical precision with electrical efficiency, offering manufacturers improved productivity, reduced costs, and superior component quality.