Introduction

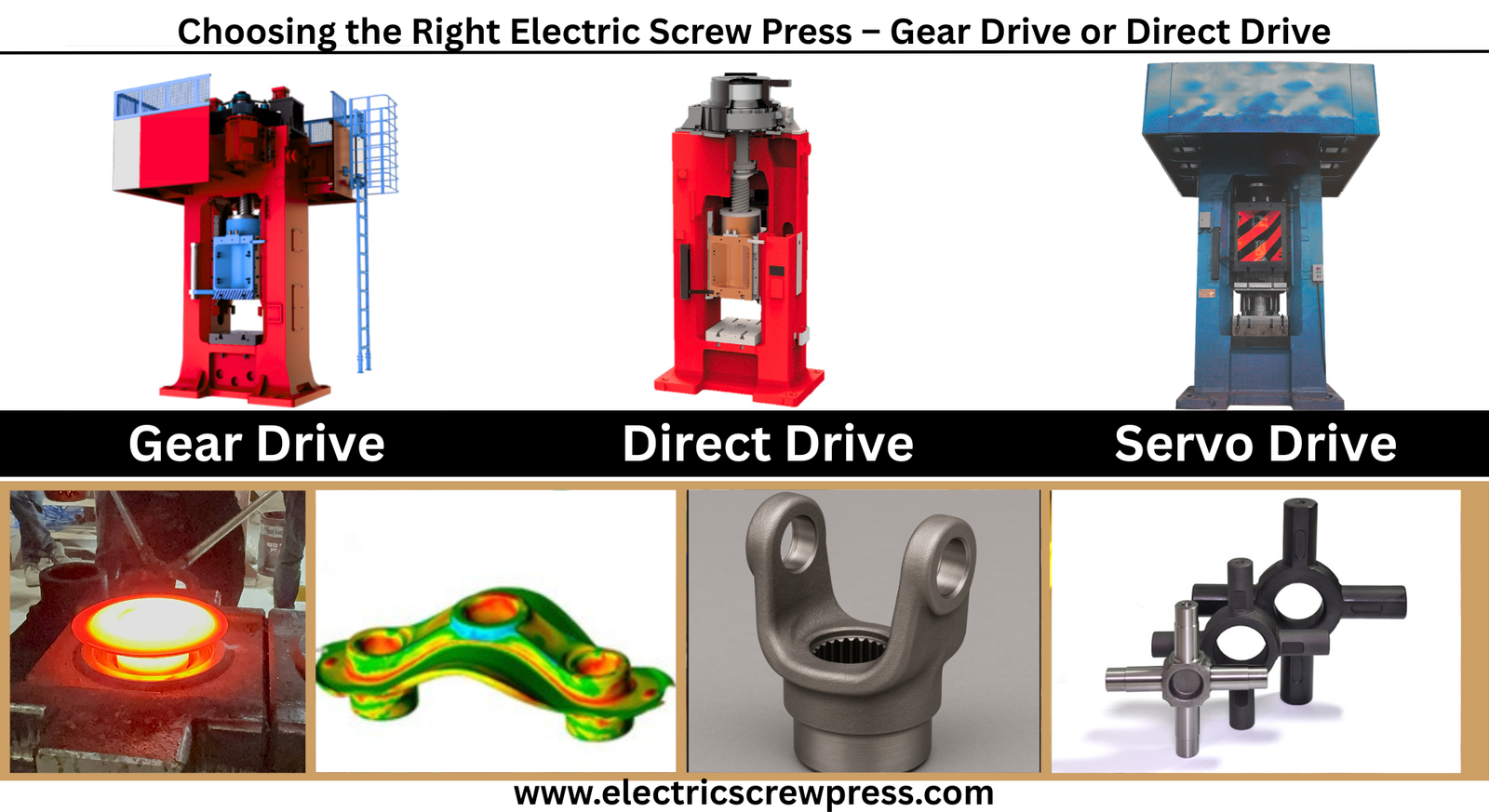

Electric Screw Presses are the backbone of closed die forging plants. They combine high forging accuracy, controlled energy, and durability. But before buying a screw press, it’s important to understand the three main types available today: Gear Drive, Direct Drive, and Servo Drive (CNC). Each has its own benefits, limitations, and applications.

1. Gear Drive Electric Screw Press

This is the traditional screw press type, widely used for decades.

-

Working: Uses a flywheel and gear transmission to rotate the screw.

-

Advantages:

-

Rugged and simple design.

-

Suitable for heavy-duty forgings.

-

Lower upfront cost compared to advanced models.

-

-

Limitations:

-

Higher energy loss due to gear friction.

-

More maintenance (lubrication, wear & tear of gears).

-

Less precise compared to new-generation presses.

-

2. Direct Drive Electric Screw Press

Direct Drive models remove the gear system completely.

-

Working: The motor is directly connected to the screw for instant torque transfer.

-

Advantages:

-

Higher accuracy in energy control.

-

Reduced power loss, better efficiency.

-

Lower maintenance as there are no gears.

-

Compact design, less vibration.

-

-

Limitations:

-

Higher cost than gear-driven presses.

-

Requires skilled operators for optimum use.

-

3. Servo Drive (CNC) Electric Screw Press

This is the latest innovation in forging technology, also known as servo-electric or inverter-driven screw press.

-

Working: Uses servo motors + inverter drives controlled by PLC, allowing full programmability.

-

Advantages:

-

Maximum precision in stroke depth and forging energy.

-

Energy saving up to 30–40% compared to old presses.

-

Fully compatible with Industry 4.0 automation – robots, manipulators, automatic spray.

-

Longer die life and improved forging quality.

-

-

Limitations:

-

Highest initial investment.

-

Requires skilled operators and trained service team.

-

Side-by-Side Comparison

| Feature | Gear Drive Press | Direct Drive Press | Servo Drive Press (CNC) |

|---|---|---|---|

| Accuracy | Low–Medium | High | Very High |

| Energy Efficiency | Moderate (loss in gears) | Better (direct motor link) | Best (servo controlled) |

| Maintenance | High (gears, wear parts) | Low | Very Low |

| Automation | Basic | Semi-automatic | Fully automatic ready |

| Cost | Low | Medium | High |

| Best For | Heavy-duty, basic parts | Precision forging, general | Aerospace, Auto, Medical |

Which One Should You Choose?

-

If budget is the main factor → Gear Drive Screw Press.

-

If you want balanced performance & lower maintenance → Direct Drive Screw Press.

-

If you need precision forging, energy savings & future automation → Servo Drive (CNC) Screw Press.

Choose Us – Click Here More Details

Before buying a screw press, evaluate your product range, tonnage requirement, automation level, and ROI goals. The Electric Screw Press Group offers all three types – Gear Drive, Direct Drive, and Servo Drive – from 250 tons to 8500 tons, giving you the flexibility to choose the best machine for your forging plant.