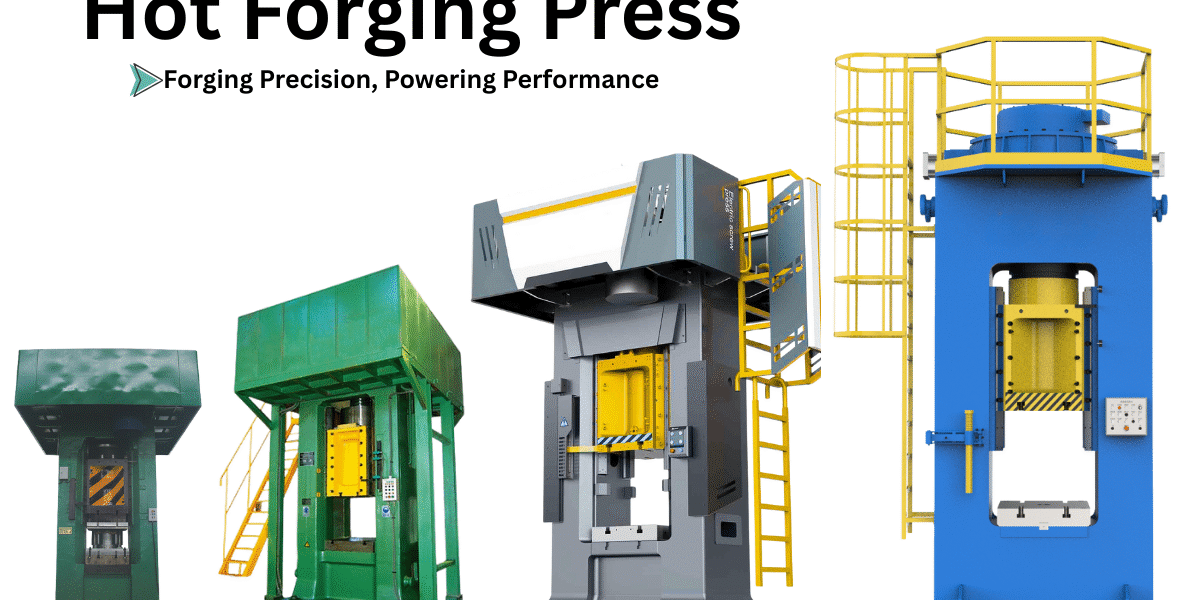

Hot Forging Press Manufacturer – Electric Screw Press Group

At Electric Screw Press Group, we are a leading Hot Forging Press Manufacturer, delivering world-class forging solutions to industries across the globe. With years of experience and expertise in forging technology, we specialize in designing, manufacturing, and supplying all types of hot forging presses tailored to meet diverse production needs. Our presses are engineered for precision, durability, and energy efficiency, enabling manufacturers to produce high-quality forged components for automotive, aerospace, defense, medical, oil & gas, and heavy machinery sectors.

We manufacture a wide range of Hot Forging Presses, including:

- Mechanical Press – Ideal for high-speed forging operations with consistent force, capable of handling a variety of ferrous and non-ferrous materials. Our mechanical presses are designed to provide smooth operation, high tonnage, and long die life, ensuring maximum productivity.

- Electric Screw Press – Engineered for high precision and energy efficiency, our electric screw presses offer controlled tonnage and stroke for accurate forging. Perfect for aluminum alloys, titanium, and complex steel components, these presses are low-maintenance and suitable for multi-shift operations.

- Direct Drive Screw Press – With the motor directly mounted on top, our direct drive screw presses deliver servo-controlled precision, minimal energy loss, and consistent tonnage throughout the stroke. These presses are ideal for forging high-strength alloys like Inconel, Duplex Steel, Titanium, and Aluminum, ensuring minimal scrap and maximum material yield.

- Servo Drive Press – Designed for automation-ready operations, our servo drive presses offer dynamic control of tonnage and stroke, enabling rapid product changeovers while maintaining superior component quality. These presses are perfectly suited for aerospace, defense, and precision automotive components.

- Power Press – Our power presses provide high-force forging capability with robust construction and reliability for large-scale production of flanges, shafts, couplers, and heavy industrial components.

- Trimming Press – Specifically designed for precision trimming and piercing operations, our trimming presses can handle 1 mm to 10 mm cutting thickness while ensuring minimal material wastage and high accuracy.

At Electric Screw Press Group, we focus not only on supplying state-of-the-art hot forging presses, but also on delivering end-to-end turnkey solutions. From die design, forging simulation, process optimization, installation, commissioning, and training, we provide a complete forging ecosystem to enhance efficiency, yield, and profitability.

Our presses are built with high-grade materials, advanced technology, and precision engineering, ensuring long service life, low maintenance, and consistent output quality. With capabilities to forge ferrous and non-ferrous metals, exotic alloys, and lightweight aluminum components, our equipment caters to industries requiring high precision, high strength, and durable components.

By choosing Electric Screw Press Group as your Hot Forging Press Manufacturer, you are partnering with a company that combines innovative technology, expert engineering, and global best practices to deliver forging solutions that maximize productivity, reduce operational costs, and elevate product quality.

Whether you are setting up a new forging plant or upgrading your existing line, our team ensures a seamless integration of machinery, automation, and process expertise, helping you achieve high-precision forging results for a wide variety of materials and applications.

We are committed to excellence, innovation, and customer satisfaction, making Electric Screw Press Group the preferred choice for hot forging press solutions worldwide.

Note: Know More About It