How to Forge Inconel Components for Aerospace and Defense

Forging Inconel for aerospace and defense applications demands precise control over heat, deformation, and microstructure to produce high-strength, fatigue-resistant components such as turbine disks, rings, seals, valves, and fasteners. Adhvika Forge Tech specializes in delivering turnkey Inconel forging solutions, including plant setup, press selection, die design, process control, and post-forging treatment for critical applications.

Inconel Forging Solutions for Aerospace and Defense by Adhvika Forge Tech

Forging Inconel for aerospace and defense applications demands precise control over heat, deformation, and microstructure to produce high-strength, fatigue-resistant components such as turbine disks, rings, seals, valves, and fasteners. Adhvika Forge Tech specializes in delivering turnkey Inconel forging solutions, including plant setup, press selection, die design, process control, and post-forging treatment for critical applications.

1. Alloy Selection

The choice of alloy determines performance, corrosion resistance, and fatigue life:

- Inconel 718: Precipitation-hardened superalloy offering high strength up to ~700°C. Ideal for turbine hot-section hardware and high-performance fasteners. Provides excellent fatigue and creep resistance.

- Inconel 625: Solid-solution strengthened alloy known for superior corrosion and oxidation resistance, often used in valves, seals, marine applications, and aggressive environments.

Selecting the right alloy is critical for matching mechanical properties, service temperature, and corrosion requirements.

2. Pre-Forge Conditioning

- Start with certified mill stock, perform solution anneal or homogenization per alloy specifications to dissolve precipitates and ensure uniform composition.

- Maintain clean surfaces and avoid sulfur or oxygen contamination. Use neutral or low-sulfur lubricants and insulating blankets during transfers to prevent surface oxidation and scale formation.

- Pre-forge inspection ensures no surface defects that could compromise final component integrity.

3. Heating Window

Proper heating is critical to maintain workability and grain structure:

- Inconel 718: Forge in high sub-solvus to supersolvus temperature ranges; control soak time to limit grain growth and prevent incipient melting.

- Inconel 625: Use a slightly lower hot-work range, reheating frequently to manage flow stress without overheating.

- Uniform heating with protective furnace atmospheres ensures consistent material properties throughout the forging billet.

4. Press Selection and Load

- Hydraulic and electric screw presses with closed-loop load and displacement control are preferred for nickel-based superalloys.

- Calculate required press load using alloy flow-stress data at forging temperatures.

- Always select a press with a generous load margin to accommodate high hot strength and reduce dwell time, minimizing heat loss.

5. Deformation Strategy

- Use multiple high-reduction passes rather than numerous small bites.

- Maintain metal within target temperature to avoid edge chilling and cracking.

- Apply controlled strain rates: too fast risks cracking; too slow increases friction and cooling. Reheat as necessary when the surface dulls.

- Align fiber/axial grain flow with principal stress directions in rings, disks, and valves to maximize fatigue resistance.

6. Die Design

- Use hot-work tool steel with generous fillet radii, streamlined flash gutters, and proper draft to maintain metal flow and reduce stress concentration.

- Design preforms to promote uniform deformation and axial grain orientation in disks, rings, valves, and nozzles.

- Proper die design extends die life, reduces press load, and improves component quality.

7. Cycle Time and Reheats

- Keep transfer times short using insulated handling equipment.

- Plan reheats as soon as the metal drops below the lower hot-work limit.

- For upset and ring operations, maintain quick cycles and temperature equalization so core and surface temperatures remain uniform.

8. Post-Forge Heat Treatment

- Inconel 718: Perform solution treatment followed by aging to develop γ′/γ″ precipitation strengthening. Ensures high tensile, creep, and fatigue strength for aerospace components.

- Inconel 625: Stabilize/anneal to restore corrosion resistance and ductility after heavy reductions.

9. Machining and Finishing

- Use rigid setups, sharp carbide or CBN tools, and flood coolant for minimal heat input during rough and finish machining.

- Perform NDT inspections including ultrasonic testing (UT), magnetic particle inspection (MPI), and dye penetrant tests.

- Dimensional inspection is critical for flight-critical aerospace and defense components.

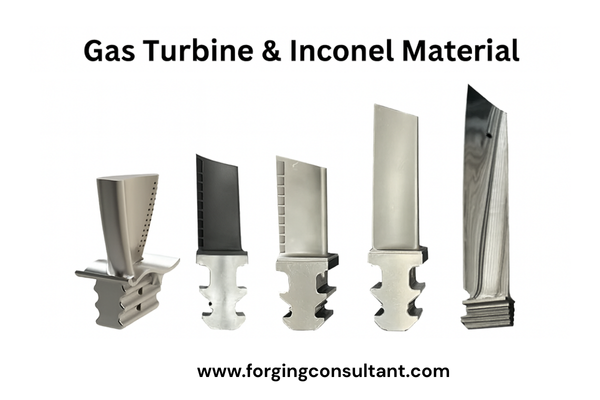

10. Typical Applications

- Aerospace: Turbine disks, rings, seals, combustor hardware, and high-temperature fasteners.

- Defense: Valves, nozzles, missile/rocket hot-end parts, corrosion-resistant downhole components, and militarized energy systems.

11. Adhvika Forge Tech Capabilities

- Expertise in die design, press-load optimization, and cycle control to reduce press load, extend die life, and improve energy efficiency.

- Complete process control from preform through aging ensures consistent grain flow, minimal buy-to-fly ratio, and repeatable properties.

- Turnkey solutions for Inconel 718 and 625: plant setup, automation, press selection, and process monitoring for aerospace and defense qualification.

Step-by-Step Summary:

- Alloy selection: 718 or 625 depending on strength and corrosion needs.

- Pre-forge conditioning: annealing, surface cleaning, lubrication.

- Controlled heating window to maintain uniform metal flow.

- Press selection: hydraulic or electric screw press with proper load.

- Deformation strategy: multiple high-reduction passes, controlled strain rates.

- Die design: hot-work tool steel, fillet radii, axial grain alignment.

- Cycle and reheats: minimize transfer time, quick reheat cycles.

- Post-forge heat treatment: precipitation hardening or stabilization.

- Machining & finishing: rigid setups, sharp tools, NDT & dimensional inspection.

- Applications: aerospace turbine hardware, defense valves/nozzles.

- Adhvika Forge Tech: turnkey solution, energy-efficient, precise, high-quality forging.

Note: All temperatures, loads, and timings should strictly follow AMS/ASTM specifications for the exact alloy lot and component geometry to ensure component reliability and compliance.

#Inconel #Duplex #Titanium #Aluminum #Alloy #Forgingsolution #ElectricScrewPress