India’s Best Closed Die Forging Press Manufacturer – Complete Press & Plant Installation Guide

Closed Die Forging – The Backbone of Modern Manufacturing

Closed die forging, also known as impression-die forging, is one of the most reliable and widely used methods in the forging industry. In this process, hot billets are pressed between two precision dies, forcing the metal to flow into the exact cavity shape. This method ensures superior strength, excellent dimensional accuracy, and minimal machining, making it ideal for critical components in automotive, aerospace, defense, oil & gas, medical, and heavy engineering sectors.

Why Choose Closed Die Forging?

-

High accuracy and repeatability for complex shapes.

-

Superior grain flow and fatigue resistance.

-

Reduced material wastage compared to machining or casting.

-

Excellent surface finish and near-net-shape production.

-

Suitable for a wide range of materials – carbon steel, alloy steel, stainless steel, aluminum, titanium, and super alloys like Inconel.

Electric Screw Press Group – Powering Forging Innovation

The forging industry is transforming with the arrival of Electric Screw Presses. Unlike traditional hammers and friction screw presses, Electric Screw Presses from Electric Screw Press Group deliver:

-

Precise energy control with inverter drives.

-

Up to 30% energy savings compared to conventional presses.

-

Low noise, low maintenance, and eco-friendly operation.

-

Integration with robots, manipulators, and automatic graphite spray systems for Industry 4.0-ready forging lines.

This innovation ensures consistent forging quality, longer die life, and reduced operational cost.

Innovation of Electric Forging Press in India

India is witnessing rapid adoption of Electric Screw Presses, replacing outdated mechanical and friction presses. These presses combine precision, digital monitoring, and energy efficiency, enabling Indian manufacturers to compete globally. From titanium aerospace parts to medical implants and automotive components, the future of forging lies in Electric Screw Press-driven closed die forging plants.

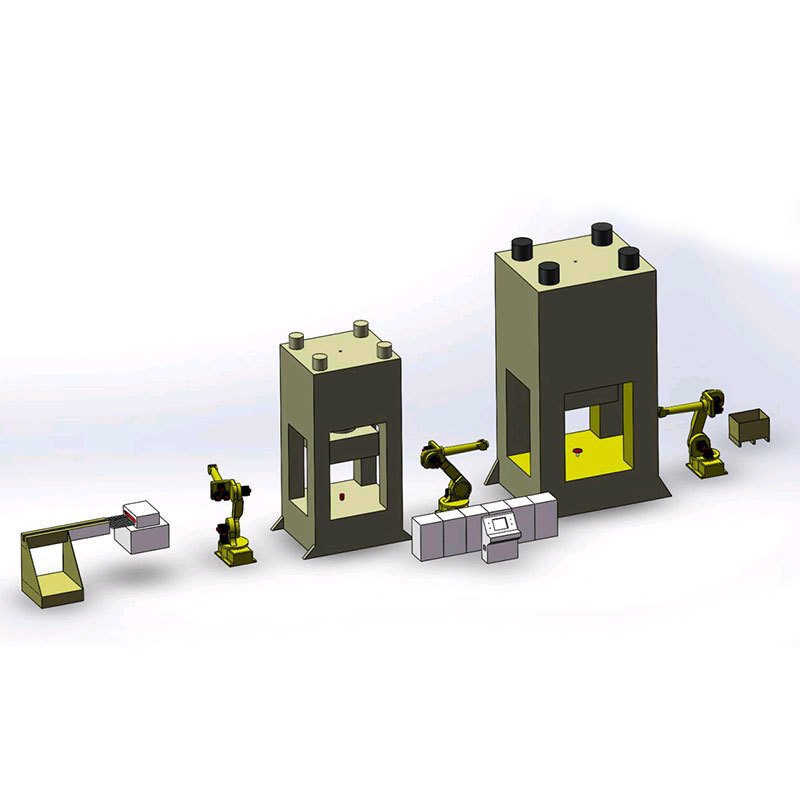

Why Closed Die Forging is Best for Complex Shapes – Forging Press Plant Setup Explained

How to Setup a Closed Die Forging Plant in India

-

Define Product Range

Decide your focus – automotive gears, shafts, aerospace turbine blades, orthopedic implants, oil & gas flanges, or defense parts. -

Select the Right Press

Choose an Electric Screw Press based on tonnage requirements (250–8500 tons). Smaller parts may need 400–630 tons, while heavy shafts or aerospace parts may need 1600–3150 tons. -

Install Auxiliary Equipment

-

Billet heating furnaces (induction or gas).

-

Descaling machines for scale removal.

-

Trimming presses for flash cutting.

-

Forging manipulators/robots for handling.

-

-

Design & Simulation of Dies

Use advanced CAD/CAM and forging simulation software to design dies, ensuring correct metal flow and higher yield. -

Foundation & Installation

Heavy presses require anti-vibration foundations for stability. Proper installation by experts ensures longer machine life. -

Automation & Safety

Integrate robots and handling systems for higher productivity and operator safety. -

Production & Quality Control

Begin trial production, validate grain flow, dimensional accuracy, and surface finish, then shift to mass production.

India’s Best Closed Die Forging Manufacturer – Setup forging plants with Electric Screw Press, turnkey solutions, and modern press innovation.

Forging Machine & Forging Solution – Click Here