Electric Screw Press – The Game Changer in the Forging Industry

The forging industry is witnessing a significant transformation with the introduction of the Electric Screw Press (ESP). Traditional forging methods such as mechanical presses, belt drop hammers, and conventional forging techniques have served the industry for decades, but they come with inherent limitations like high energy consumption, lower precision, increased die wear, and dependency on manpower. The Electric Screw Press is poised to redefine forging operations, offering manufacturers unmatched advantages in precision, efficiency, and automation.

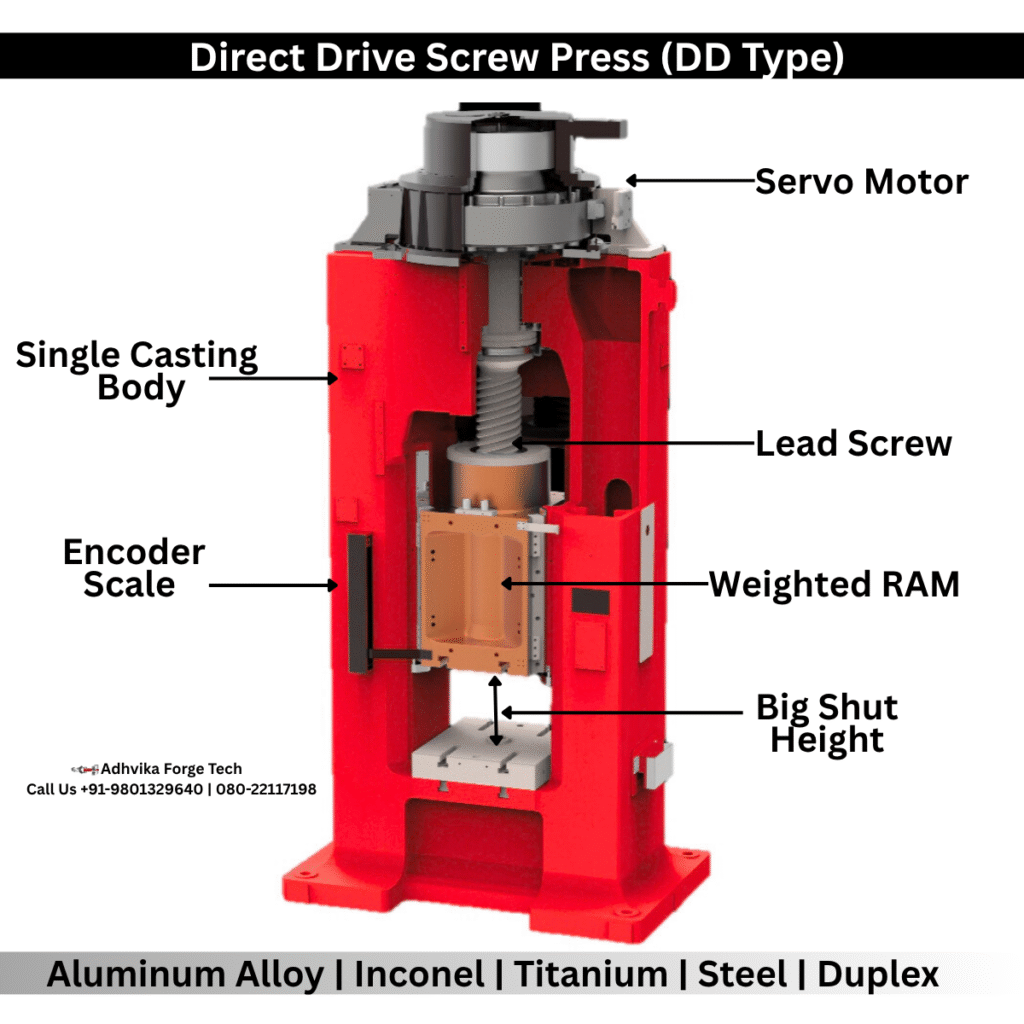

At its core, an Electric Screw Press uses an electrically driven screw mechanism to convert rotational motion into linear pressing force. Unlike mechanical presses that rely on flywheels or belt drives, the ESP is powered by a single top-mounted electric motor (in case of direct drive) or optimized gear-driven motors, delivering consistent and precise force to the ram. This controlled force ensures that the metal blank flows accurately into the die cavity, creating components with high dimensional accuracy, superior surface finish, and enhanced mechanical properties.

One of the most significant advantages of the Electric Screw Press is energy efficiency. Traditional mechanical presses consume large amounts of energy due to continuous flywheel operation, even during idle periods. In contrast, the ESP uses energy only during the forging stroke, resulting in substantial savings. Companies adopting ESP technology report reduced electricity consumption by up to 40–50%, lowering operational costs and contributing to sustainable manufacturing practices.

Another critical benefit is the extended die life. Controlled and precise force application reduces impact stress and uneven wear on dies, prolonging their usability and reducing the frequency of costly die replacements. This ensures a stable production cycle with minimal downtime, which is essential for industries like automotive, aerospace, defense, and heavy engineering where quality and delivery timelines are crucial.

Electric Screw Press – India’s Best Manufacturer, Offering High-Precision, Energy-Efficient Forging Solutions for Automotive, Aerospace & Industrial Components

Automation capabilities of the Electric Screw Press make it an ideal choice for modern manufacturing environments. The press can be integrated with robotic part handling, automatic feeding systems, and material preheating units, creating a fully automated forging line. Additionally, AI-based production management systems can monitor every stroke, calculate output per shift, optimize cycle time, and provide predictive maintenance alerts. This not only enhances productivity but also reduces dependency on skilled manpower, making operations safer and more efficient.

The ESP is versatile and can forge a wide range of materials, including ferrous and non-ferrous metals, aluminum alloys, titanium, and other high-strength materials. Its precision and control allow the production of complex shapes and critical components like automobile crankshafts, control arms, aerospace parts, defense components, and high-performance industrial machinery parts. Even lightweight materials like aluminum alloys benefit from precise forging that maintains strength while reducing material waste.

From a technical perspective, the Electric Screw Press offers adjustable stroke length, ram velocity, and force control, allowing operators to fine-tune the process for different materials and component geometries. Its direct drive design minimizes mechanical losses and vibration, delivering high repeatability and uniformity across batches. Advanced presses also come with multi-stage control, where upsetting, blocking, and finishing strokes can be programmed and monitored digitally, improving overall forging accuracy.

Operational benefits include:

- High precision forging with consistent component quality

- Energy savings through efficient motor operation

- Longer die life due to controlled force application

- Automation-friendly for robotic integration and AI-based monitoring

- Reduced manpower dependency and safer working conditions

- Faster production cycles with predictable output

- Capability to forge complex geometries in high-strength materials

- Sustainable and cost-effective operations for long-term ROI

Industry feedback confirms that manufacturers using Electric Screw Presses experience higher throughput, lower scrap rates, and improved yield. The ability to monitor and analyze production digitally allows managers to make informed decisions, optimize processes, and plan maintenance proactively, which is not possible with older mechanical systems.

In conclusion, the Electric Screw Press is truly a game changer for the forging industry. It merges precision, efficiency, and automation in a single system, addressing the limitations of traditional forging methods while enhancing productivity and profitability. By adopting ESP technology, forging manufacturers can stay competitive in a rapidly evolving industrial landscape, delivering high-quality, reliable, and cost-effective components to meet the demands of modern industries worldwide.

With continuous advancements in electric motor technology, AI-based process control, and automation, the future of forging is clearly moving towards fully electrified, digitally monitored, and highly precise forging presses. The Electric Screw Press is leading this revolution, proving that innovation in forging is not just about shaping metal, but shaping the future of manufacturing itself.