Reduce Roll Machine

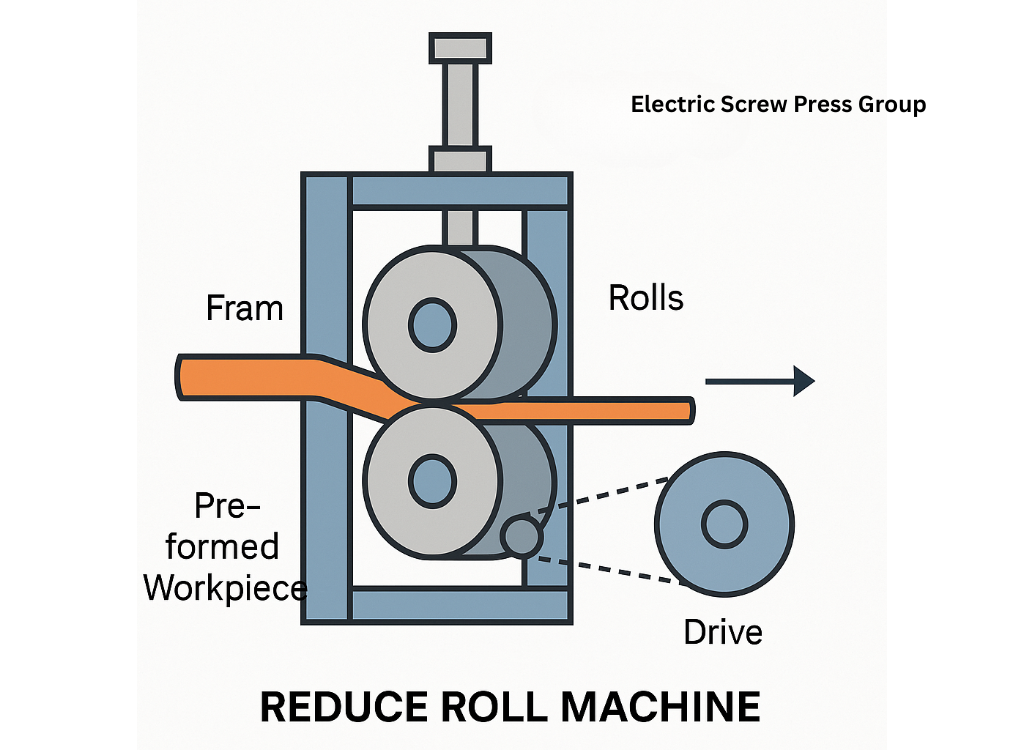

Reduce Roll Machine is designed for pre-forming metal components before they proceed to the final forging operation. Its working principle is based on progressive rotary deformation. The machine features precision-engineered rolls mounted on high-strength shafts, which are rotated by a motorized drive system. The workpiece passes through these rolls, which apply controlled compressive and tensile forces, gradually reducing its cross-section while maintaining uniform elongation. The deformation is carefully calculated to prevent material cracking, surface defects, or work hardening beyond desired limits.

High-precision Reduce Roll Machine for pre-forming metal components. In-house manufacturing, custom die design, energy-efficient, and unlimited service guarantee

The machine design includes:

- Heavy-duty frame and bearings to withstand high rolling loads.

- Adjustable roll gap for different material thicknesses and diameters.

- High-torque motor with variable frequency drive (VFD) for precise speed and force control.

- Temperature-controlled pre-heating options for hot and warm forging materials.

- Hydraulic or mechanical roll adjustment for fine-tuning the deformation profile.

- Integrated sensors and PLC controls for monitoring roll pressure, feed speed, and torque to ensure consistent quality.

Components Produced:

The Reduce Roll Machine is versatile, capable of pre-forming:

- Automotive shafts, axles, and spindles

- Gears, pinions, and bevels for precise tooth profiles

- Rings, flanges, and collars with consistent OD/ID ratios

- High-strength bolts, studs, and fasteners

- Aerospace and defense titanium and aluminum alloy components

Benefits of Technical Features:

- Precise Cross-Section Control: Maintains tolerances within microns for high-strength components.

- Optimized Material Flow: Reduces internal stress, prevents micro-cracks, and improves mechanical properties.

- High Productivity: Multiple passes in one machine with controlled deformation minimize forging cycle time.

- Reduced Die Wear: Pre-forming reduces load on final forging dies, extending die life.

- Energy Efficiency: Servo-controlled motors and VFDs reduce electricity consumption while providing high torque.

- Automation Ready: PLC integration allows for automatic feed, monitoring, and real-time adjustments for repeatable quality.

Adhvika Forge Tech Advantage:

Our in-house manufacturing ensures superior quality, precise tolerances, and long machine life. We provide custom die design, tooling support, and unlimited service guarantee, making pre-forming efficient and cost-effective. The team of experienced engineers and consultants, led by Amit Singh, oversees every stage – from selection, design, manufacturing, installation, commissioning, to operator training. Our turnkey solutions ensure clients get global-standard machines at low investment, reducing material loss, improving output, and guaranteeing long-term operational reliability.

In conclusion, the Reduce Roll Machine by Adhvika Forge Tech offers high-precision pre-forming, advanced machine design, automation capability, energy efficiency, and complete technical support. This combination ensures clients achieve maximum productivity, minimum material waste, and superior component quality, making it an indispensable machine for modern forging industries worldwide.