The Next Decade in Forging: Innovation, Automation, and Growth

The forging industry is entering a transformative era, driven by rapid advancements in technology, automation, and material science. Over the next decade, forging is set to evolve from traditional methods into highly efficient, digitally integrated, and precision-driven processes that cater to the growing demands of automotive, aerospace, defense, and industrial machinery sectors.

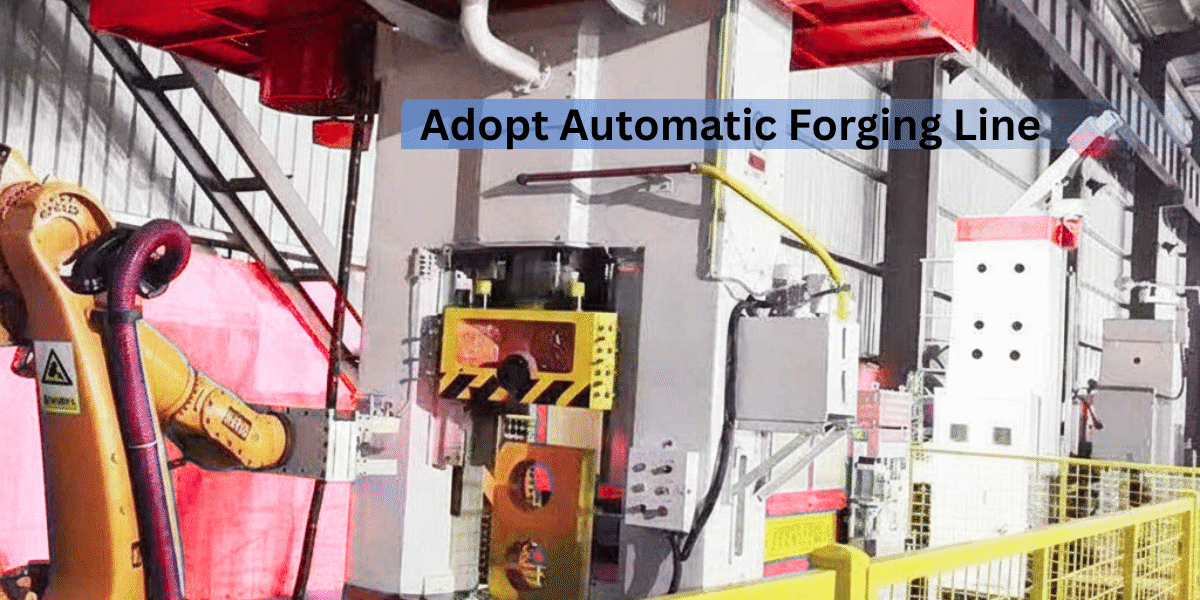

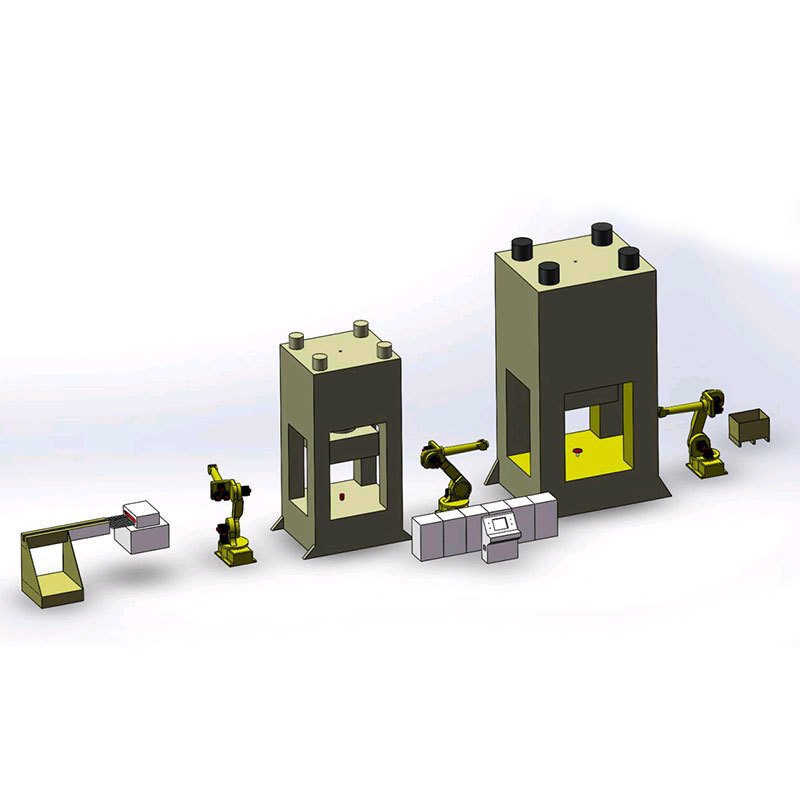

One of the key drivers of this evolution is automation. Modern forging lines are increasingly incorporating electric screw presses, servo-driven presses, and robotic handling systems to achieve consistent quality, reduce human error, and improve safety in high-temperature forging environments. Automated closed die forging lines allow manufacturers to increase throughput, reduce lead times, and lower operational costs, ensuring higher productivity while maintaining stringent quality standards.

How We Help You Set Up Modern Forging Solutions

We provide end-to-end support for setting up closed die and open die forging lines, ensuring a seamless transition from concept to full-scale production. Our approach focuses on efficiency, precision, and cost-effectiveness, helping clients achieve operational excellence in the forging industry.

1. Consultation & Feasibility Study

We begin by understanding your production requirements, part specifications, alloy types, and target output. Our team conducts a detailed feasibility study, analyzing energy needs, press capacity, tooling requirements, and space utilization to propose an optimized forging solution.

2. Forging Line Design & Layout

Our engineers design customized forging lines, including press selection (electric screw, hammer, or mechanical press), automated material handling systems, heating furnaces, and robotic handling for hot billets. We ensure optimal layout for workflow, safety, and productivity, reducing material handling time and energy consumption.

3. Equipment Supply & Integration

We supply state-of-the-art forging presses, robots, conveyors, and automation systems, integrating them into a fully functional line. Our team ensures precision installation, alignment, and calibration so the line operates at peak efficiency from day one.

4. Tooling Design & Development

Our in-house tooling experts develop dies, punches, and fixtures customized for your parts. Using advanced simulation tools, we optimize die design to reduce flash, ensure uniform deformation, and extend die life, saving material and cost.

5. Automation & Control Systems

We integrate PLC-based control systems, HMIs, and sensors to automate the forging process. This ensures real-time monitoring, predictive maintenance, energy efficiency, and consistent product quality, reducing human errors and downtime.

6. Trial Runs & Production Support

Before full-scale production, we conduct trial runs to verify die filling, press parameters, cycle times, and component quality. Our team fine-tunes the process to ensure maximum output with minimum defects.

7. Training & Knowledge Transfer

We train your operators, supervisors, and maintenance team on forging operations, safety protocols, and equipment maintenance, ensuring smooth operations and long-term reliability.

8. After-Sales & Maintenance Support

Our commitment extends beyond setup. We provide spare parts, remote assistance, on-site support, and overhauling services for presses, robots, and auxiliary equipment, ensuring uninterrupted production.

Areas Where We Help:

-

Automotive: Shafts, gears, axle components

-

Aerospace: High-strength structural and landing gear components

-

Defense: Weapon and armor-grade parts

-

Energy: Valves, turbine components, industrial machinery parts

-

General Engineering: High-precision forged components for various sectors

With Adhvika Forge Tech, clients get one-window solutions for designing, supplying, installing, and commissioning forging lines with optimized productivity, precision, and cost-effectiveness.

#adhvikaforgetech #ForgingSetup #TurnkeyForging #ClosedDieForging #ElectricScrewPress #ForgingRobots #IndustrialAutomation #PrecisionForging #ForgingConsultant #ProjectManagement