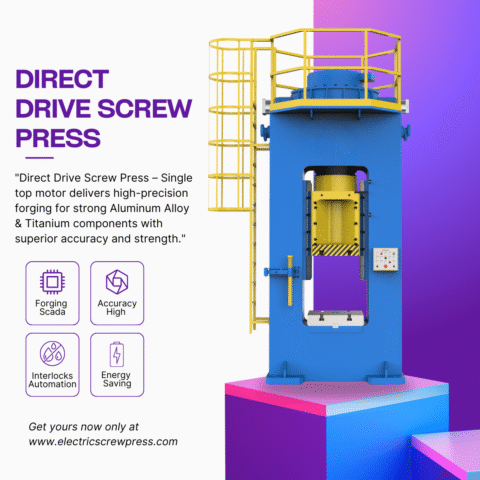

Understand why servo-driven and direct drive presses are revolutionizing forging with high precision, energy efficiency, and reduced maintenance.

In the modern forging industry, technological advancements are driving efficiency, precision, and productivity to new heights. Among these innovations, servo-driven and direct drive screw presses have emerged as game-changers. These presses are designed to overcome the limitations of traditional mechanical and hydraulic presses, providing high precision, energy efficiency, and reduced maintenance costs. Whether in automotive, aerospace, defense, or heavy engineering, industries worldwide are adopting these presses to enhance their forging operations..

Read this: forging press all type here

High Precision Forging

One of the most significant advantages of servo-driven and direct drive screw presses is their unmatched precision.

-

Accurate force control: These presses allow precise control over the applied force, ensuring consistent forging results.

-

Repeatable operations: CNC-based servo drives guarantee that every strike delivers the same force and stroke length, reducing variability.

-

Complex part manufacturing: High precision makes these presses ideal for forging automotive shafts, aerospace components, titanium, and aluminum parts that require strict dimensional accuracy.

This level of precision reduces scrap rates and ensures compliance with strict quality standards, saving both material and operational costs.

Energy Efficiency

Servo-driven and direct drive presses are significantly more energy-efficient than traditional mechanical or hydraulic presses.

-

Optimized power usage: Servo motors consume energy only when motion is required, unlike conventional presses that run continuously.

-

Reduced idle energy consumption: Direct drive systems eliminate the need for energy losses in mechanical transmissions like gears or flywheels.

-

Faster production cycles: Efficient energy use allows higher production rates with lower electricity costs.

By reducing energy consumption, these presses help companies achieve sustainable manufacturing goals while lowering operational expenses.

Reduced Maintenance and Downtime

Maintenance is a major cost factor in forging operations. Servo-driven and direct drive presses are designed to minimize wear and tear:

-

Fewer moving parts: Direct drive presses eliminate gearboxes, reducing mechanical wear and potential failure points.

-

Lower hydraulic dependency: Servo systems reduce reliance on hydraulic components that require frequent maintenance.

-

Predictive maintenance capabilities: Advanced monitoring systems allow operators to track performance and schedule preventive maintenance.

Reduced maintenance translates to less downtime, lower service costs, and longer machine lifespan, improving overall productivity.

Versatility and Process Control

Modern forging operations demand flexibility and control, which these presses provide:

-

Programmable stroke and force: Operators can adjust parameters for different materials and part geometries.

-

Multi-step forging capability: Complex forging sequences can be executed without changing machines.

-

Integration with automation: These presses are compatible with robotic handling, feeders, and forging lines, enabling fully automated operations.

This versatility allows industries to produce a wide range of components without additional investment in multiple machines.

Safety and Operator Comfort

Servo-driven and direct drive screw presses also enhance operator safety and comfort:

-

Smooth operation: Reduced vibration and noise make the workplace safer and more comfortable.

-

Controlled force application: Minimizes the risk of accidents caused by sudden machine movements.

-

Advanced monitoring systems: Allow real-time supervision without exposing operators to hazardous zones.

These features help companies maintain high safety standards while improving productivity.

Cost Savings and ROI

Although the initial investment in servo-driven or direct drive presses may be higher, the long-term benefits outweigh the cost:

-

Reduced scrap and material wastage.

-

Lower energy and maintenance expenses.

-

Higher production efficiency and uptime.

-

Capability to produce high-value, precision components for automotive, aerospace, defense, and medical sectors.

By adopting these advanced presses, forging companies can maximize ROI, maintain competitiveness, and deliver superior quality products.

One Word Last Why Best

Servo-driven and direct drive screw presses are revolutionizing the forging industry. They combine high precision, energy efficiency, reduced maintenance, versatility, safety, and long-term cost savings. As industries increasingly demand high-quality, complex components, these presses provide a reliable, modern solution to meet production challenges while boosting profitability.

Choose us for your forging solutions because we deliver turnkey projects, high-precision forging, cost-effective processes, and advanced machinery. With expert guidance from Amit Singh, we ensure energy-efficient, reliable, and high-quality production for automotive, aerospace, defense, and industrial components globally.

Also may be interesting: Here Know About Forging Industry